25-Dec-2016, Windscreen and wiper workings.

Before the chassis frame is clad with aluminium sheet, there’s a few part that need to be sorted out as they’ll be much harder to get to once the sheeting is glued – riveted in place. The first of those is the windscreen wiper motor and arm arrangement.

Previously I’d sourced a wiper motor and arm posts from a Toyota Starlet, from subsequent investigations nearly all Toyota wiper motors are the same unit. There’s a fast, slow and parking function in the motor with the intermittent function being dealt with by external electronics like timed relays etc.

Here’s a Toyota wiper motor, like mine but cleaner…

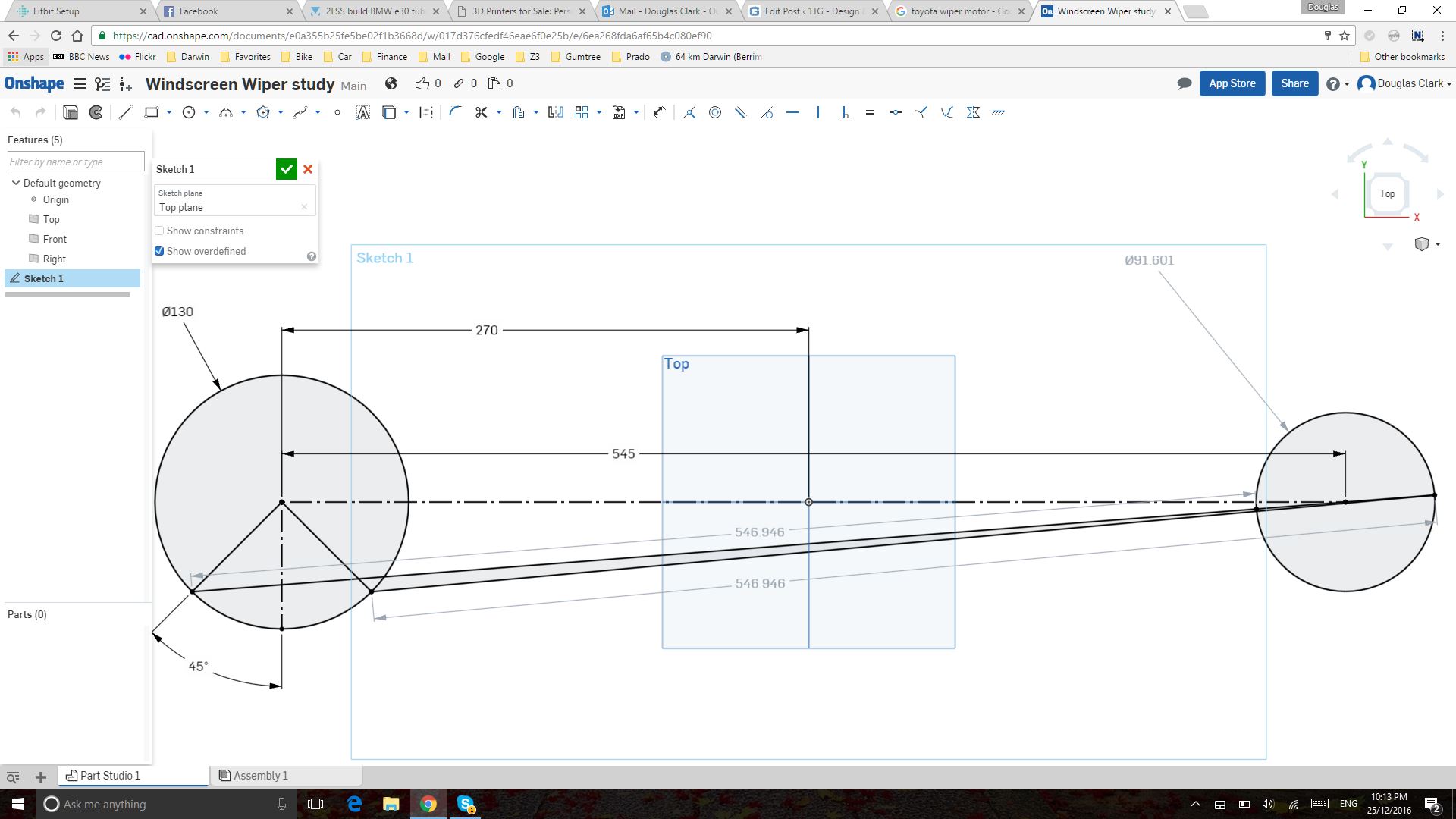

To get the motion ratio correct the lever distances were going to need adjustment The ball joint end is pressed into the rotating arm, after trying the arm on the car I found I needed a 90 degree sweep. Drawing this out in OnShape I determined the required arm radius.

The original ball joints were pressed out and replaced with 6mm THK rod ends as per the picture below:

The hole in the motor lever was welded up and re drilled in the required spot, so with that all screwed together and dodgy rod bodged up to connect it all together I got the result below…

https://vimeo.com/195167042

The wiper arm used is a modification of the one I happened to have, it’ll be replaced with new one for the real thing.

The other thing I discovered on the way was that wiper posts come in a few standard connections, as shown below, the Toyota ones appear to be the M8 type, so I’m guessing most it should not be too hard to find a decent looking one with the correct connection type.

The next item was to see if the arrangement wiped enough of the screen clean to meet the regulations. As far as I can determine though there is no specific coverage requirement in the Australian Design Rules, there is though ECE regulations ECE R43 for the Area Definition ( A & B ) and ECE R1008 for clearing % of defined areas.

Marking those areas out on the windscreen template, I got…

98% of area A is supposed to be cleared and 80% of area B. Which I think I can basically meet with a bit of work on the arm. The standard though I don’t think copes too well with low height cars as the area is too low on the screen for where I think the driver would be looking with this vehicle.