July 23, 2017. Start of the sheet metal.

There is / was a design flaw in the car in that I didn’t pay too much attention to the sizes of aluminium sheet available. As a result I ended up with a design where I should have used 2 cut down 1200 x 2400 sheets but as I didn’t think of that beforehand making the 2 sheet solution work would have been ugly.

Therefore I had to find 1 big sheet to do the whole piece, which thankfully enough was available (6100 x 1830 x 3 5083 grade) if I paid the stupid shipping cost, which I did. So now the floor of the car can be done end to end and sideways in one bit. Here it is delivered, its a bit thinker than I’d like but it was the thinnest available at the size. It was cut in half for delivery as I can deal with a 6.1m long sheet in the shed.

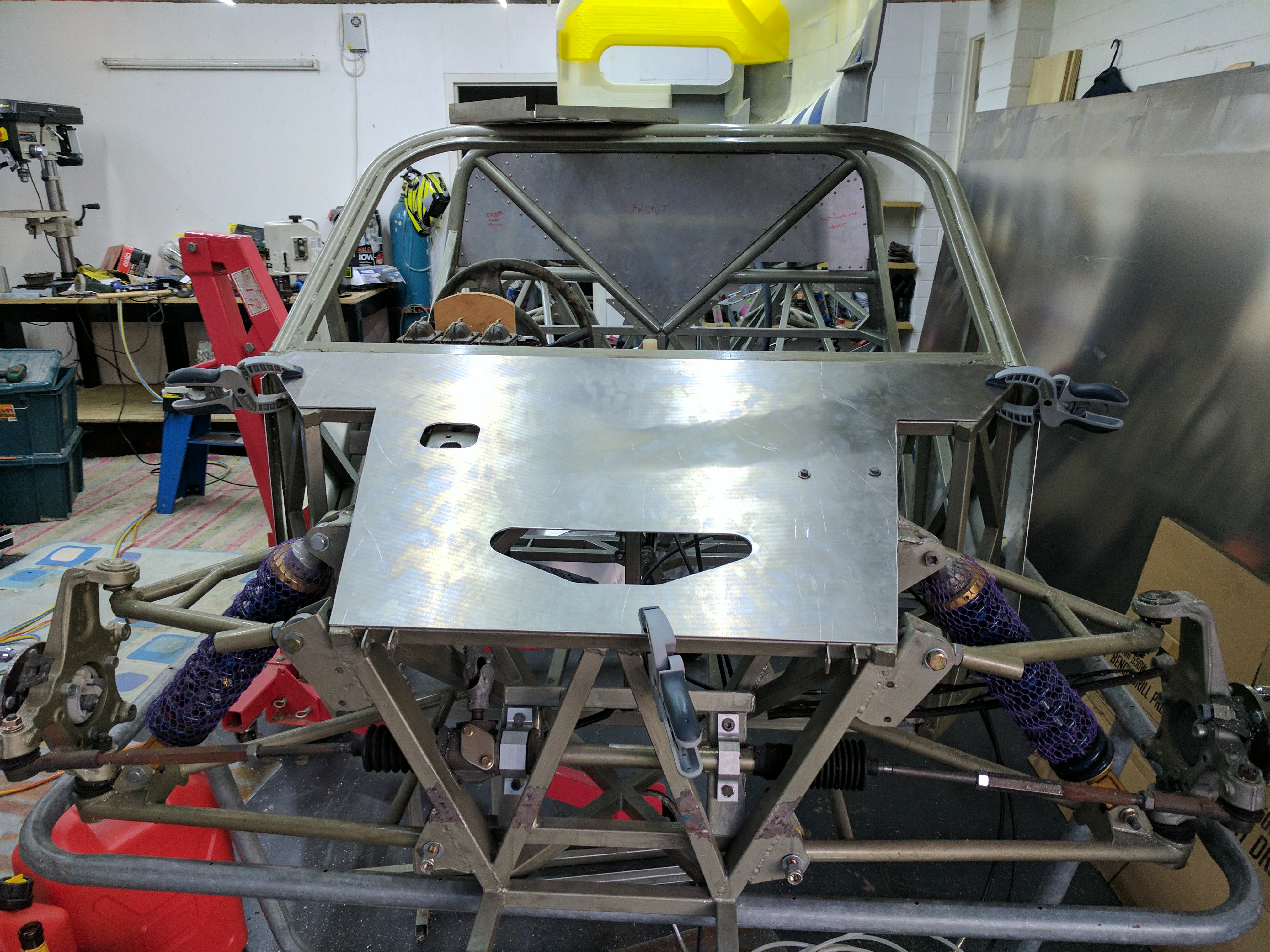

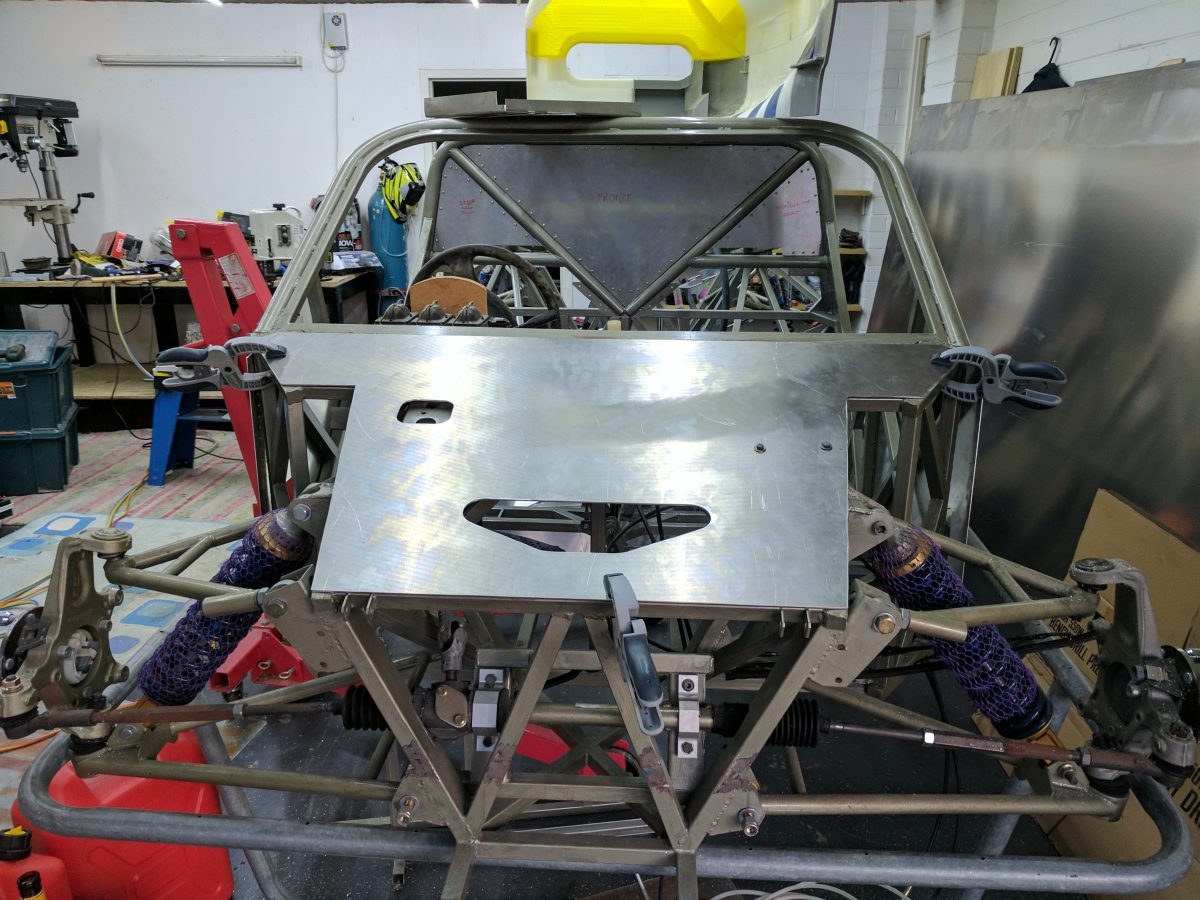

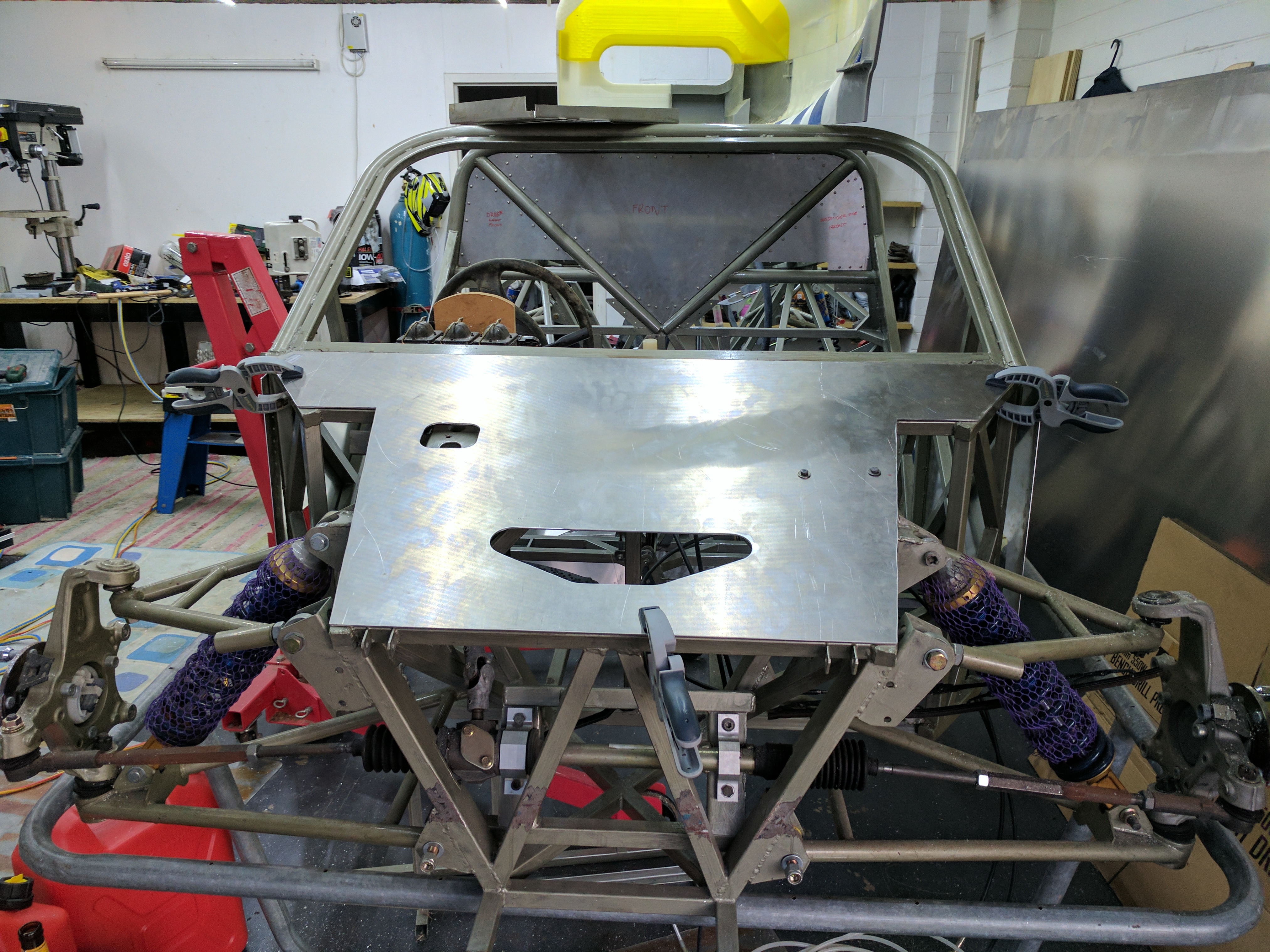

With half of it needed for the floor all the other remaining parts yet to be cut can come out of the other half. Here’s the first part made:

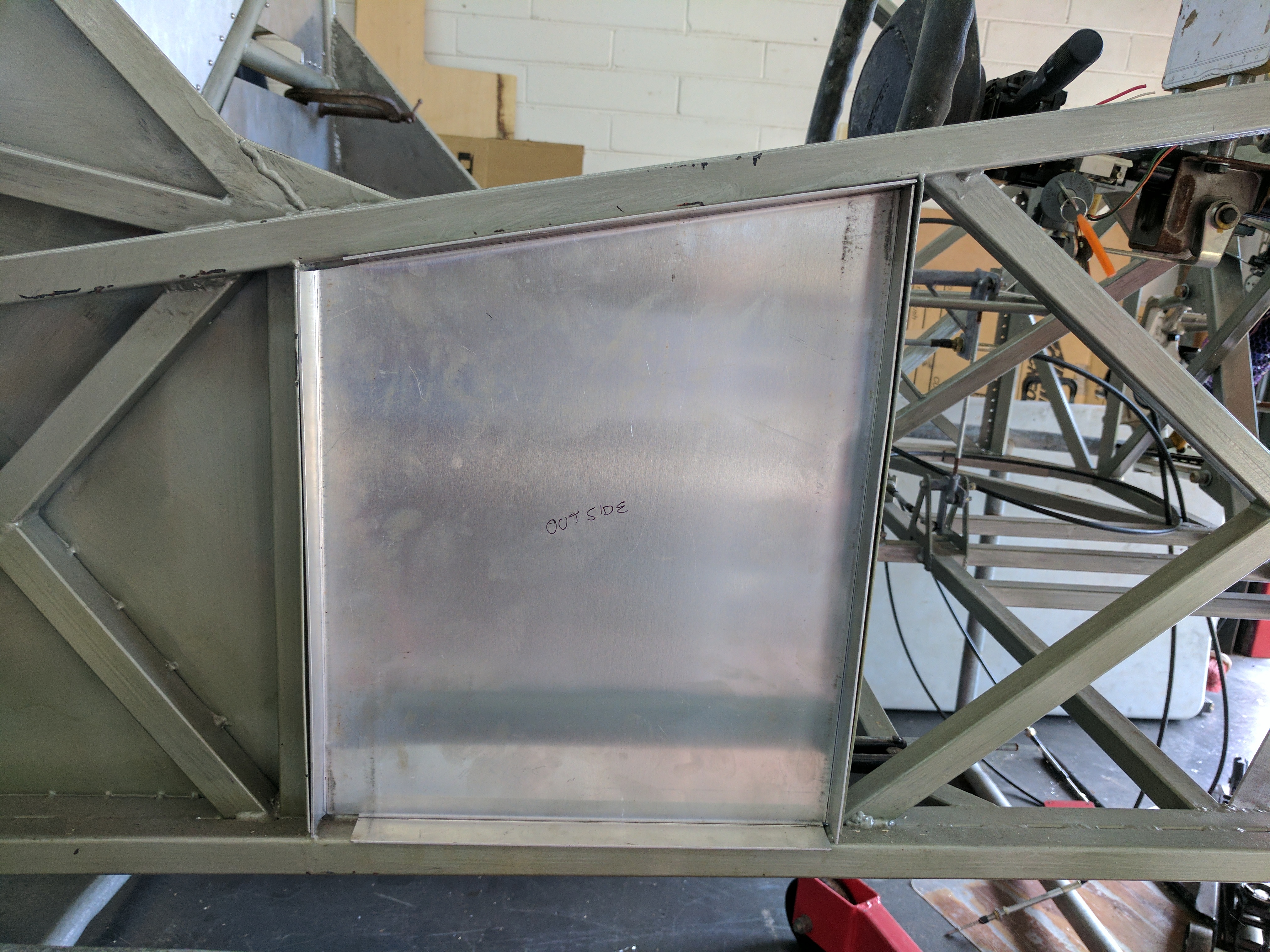

Other parts that had been laser cut in times past needed folding and fitting, I found making a wooden template to fit the hole then bending to suit worked with the tea tray type parts: